Master Rock Tools

Overview

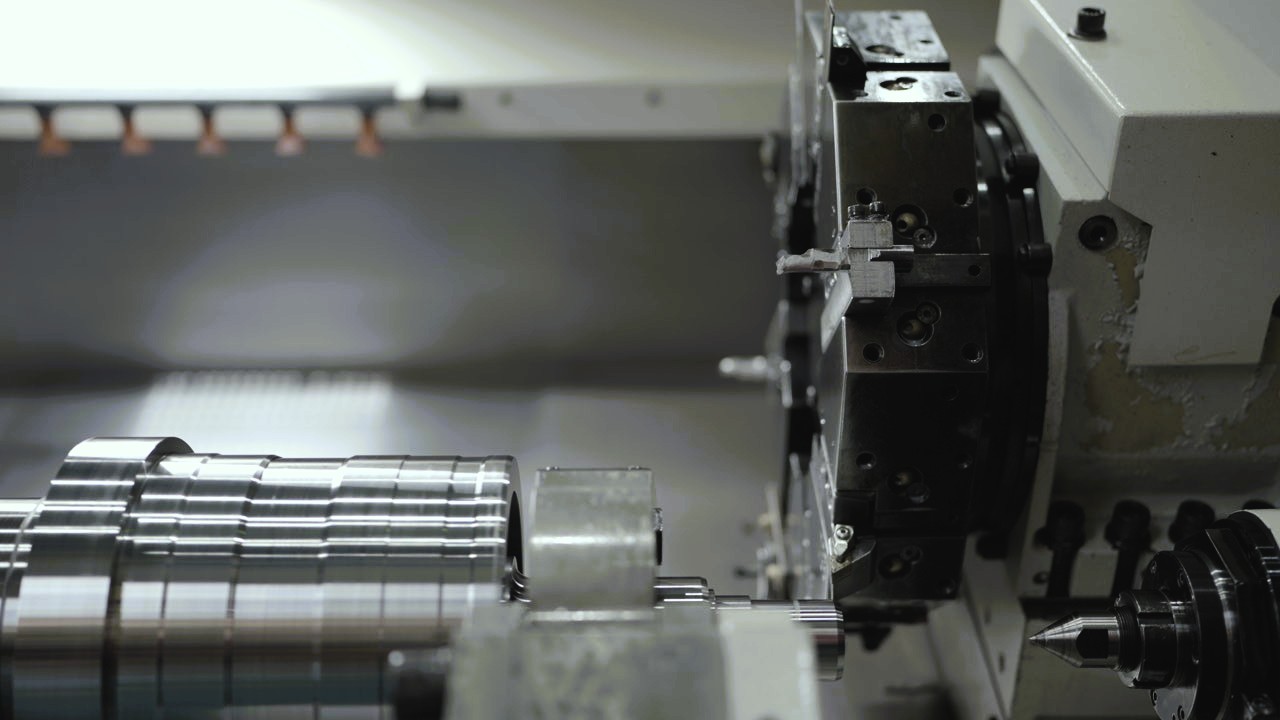

” With having high performance 20+ CNC, VMC, Milling, Drilling, Turning and Grinding machines Master Rock Tools manufacture high efficiency mining products such as Hydraulic Rock Breaker parts and Cutter Picks for Road Milling, Pilling and Coal Crushing “

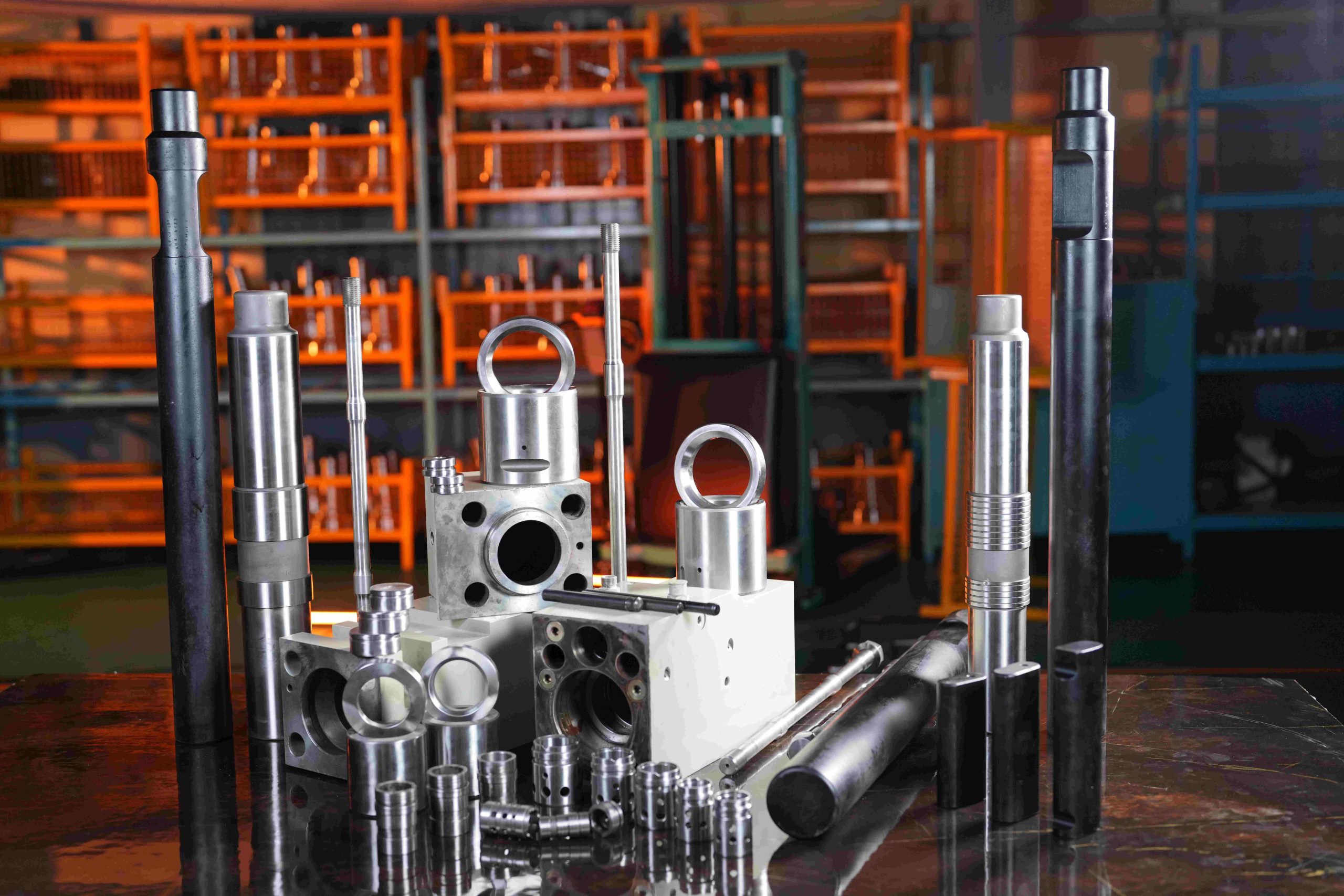

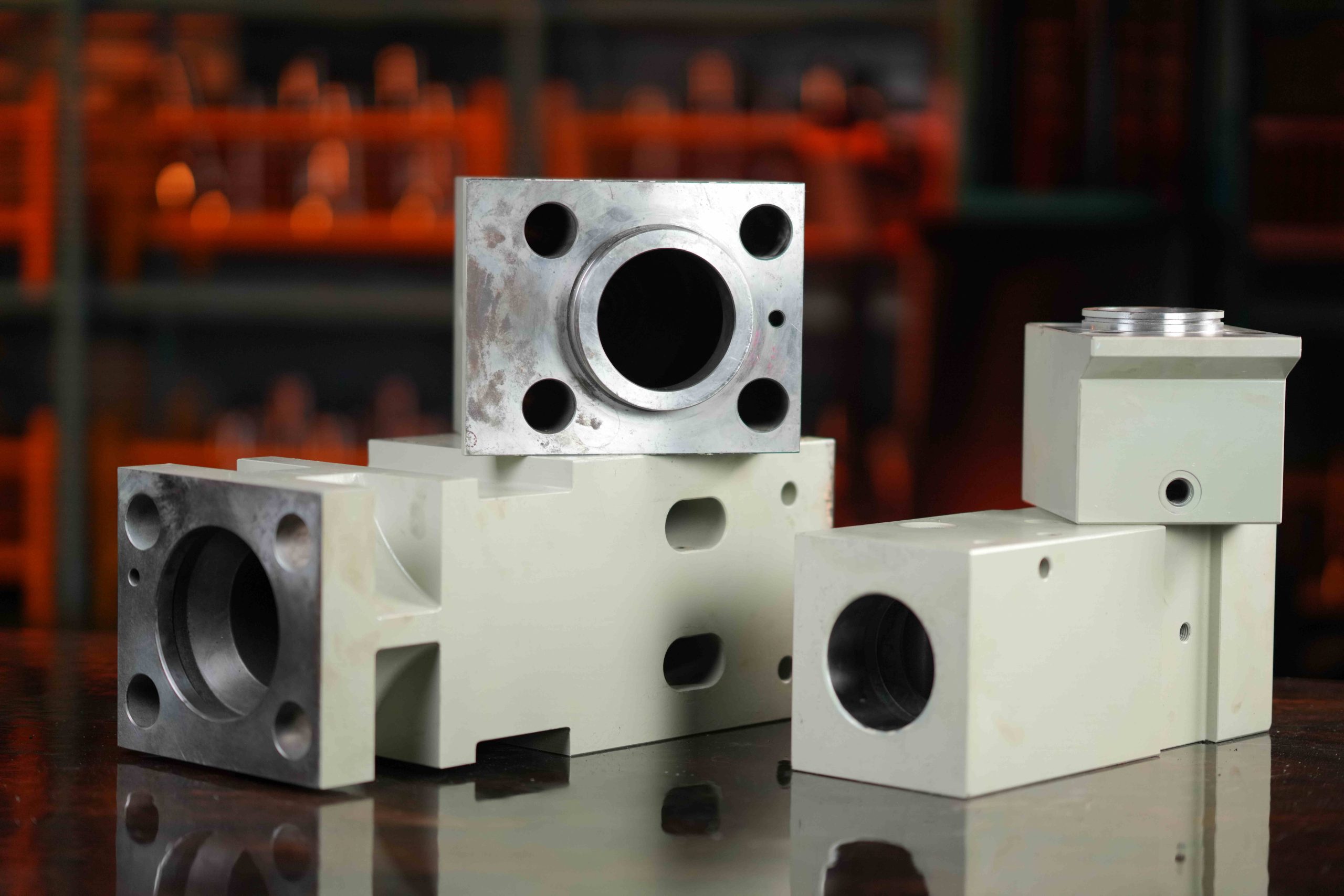

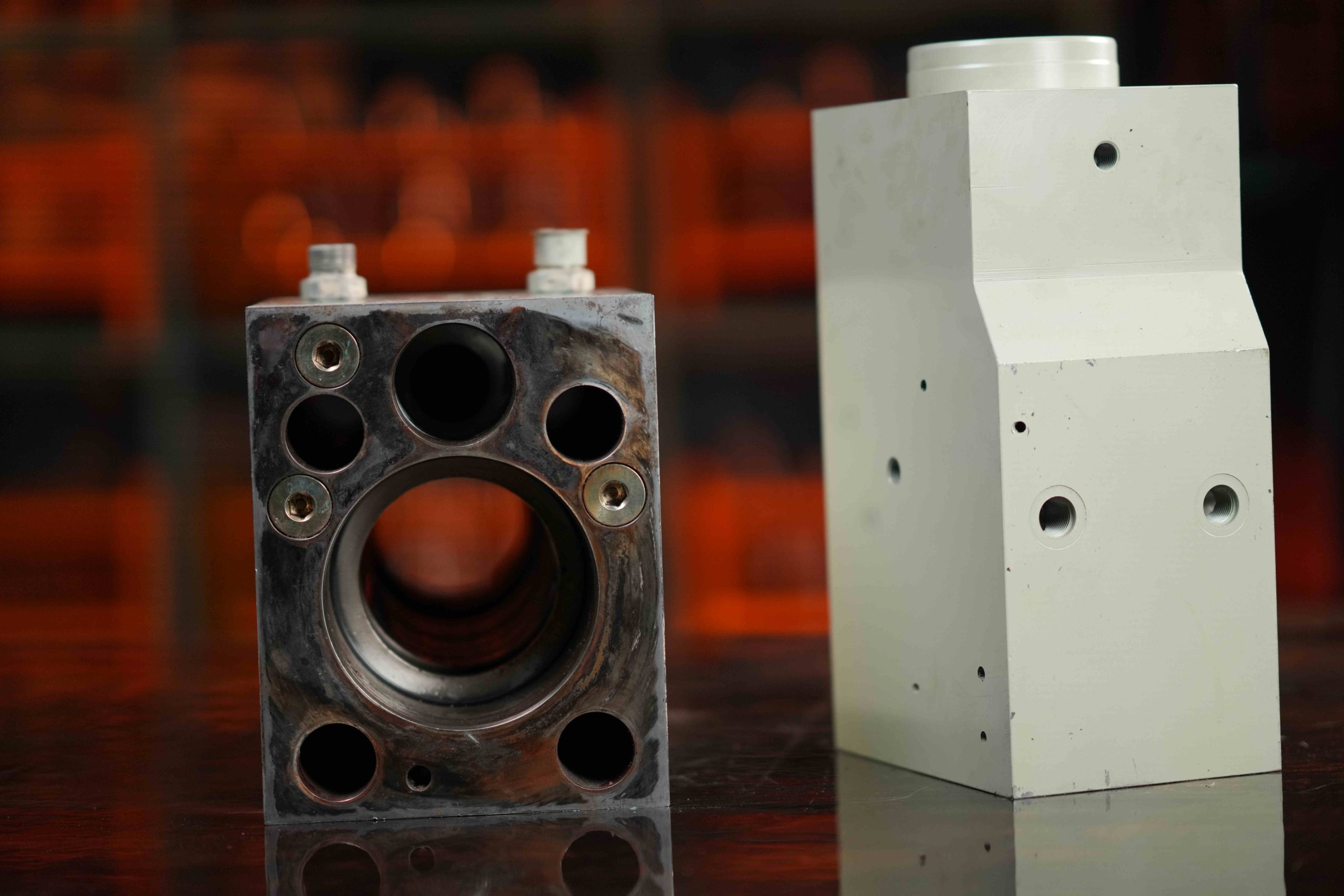

Hydraulic Rock Breaker Parts

Your Trusted Source for Uninterrupted Power, Genuine & Aftermarket Hydraulic Rock Breaker Parts for Peak Performance

At MASTER ROCK TOOLS, based in Bengaluru, Karnataka, we understand that the continuous operation of your hydraulic rock breakers is critical to your productivity in mining, quarrying, construction, and demolition. We are your reliable partner for a comprehensive range of high-quality hydraulic rock breaker parts, ensuring your equipment performs optimally and consistently, even in the most demanding Indian environments.

Key Features & Benefits:

- Exceptional Durability & Reliability: Our hydraulic rock breaker parts are engineered from premium-grade materials, including high-strength alloy steels and precision-machined components. This commitment to quality ensures superior wear resistance, impact absorption, and extended service life, drastically reducing unexpected breakdowns.

- Comprehensive Inventory: We maintain an extensive stock of critical spare parts for a wide array of hydraulic rock breaker brands and models prevalent in the Indian market. Our inventory includes, but is not limited to:

- Chisels & Moils: High-impact, wear-resistant tools for various breaking applications (conical, blunt, pyramidal, asphalt cutters).

- Pistons & Cylinders: Precision-ground components for efficient power transmission and longevity.

- Seal Kits: High-performance seals (oil seals, dust seals, nitrogen seals) designed to prevent leaks and maintain optimal pressure, even under extreme conditions.

- Accumulators & Diaphragms: Essential for shock absorption and consistent performance.

- Thru Bolts & Side Bolts: High-tensile strength fasteners to withstand immense operational forces.

- Front Heads & Bushings: Robust components to protect critical internal parts and guide the chisel.

- Valves & Regulators: For precise hydraulic control and system efficiency.

- Hoses & Fittings: Durable connections built for high-pressure environments.

- Optimized Performance & Efficiency: By supplying parts that meet or exceed OEM specifications, we help restore and maintain your rock breaker’s original breaking force and efficiency. This translates to faster job completion, reduced fuel consumption, and higher productivity per hour.

- Reduced Downtime & Cost-Effectiveness: The superior quality and longevity of our parts directly contribute to fewer part replacements and less unscheduled maintenance. Minimizing downtime means your projects stay on schedule and your operational costs are significantly lowered over the equipment’s lifespan.

- Compatibility & Fitment: Our parts are designed for seamless integration and perfect fitment with popular hydraulic rock breaker brands widely used across India ensuring hassle-free installation and reliable operation.

- Local Availability & Swift Delivery (from Bengaluru, Karnataka): Strategically located in Bengaluru, Karnataka, we leverage efficient logistics to ensure rapid dispatch and delivery of your essential parts across India. Get your equipment back to work faster with our responsive supply chain.

- Expert Technical Support: Our knowledgeable team is on hand to provide expert advice, assist with part identification, and offer technical guidance, ensuring you get the right part for your specific needs, every time.

✵ Ideal For:

- Mining Operations (granite, iron ore, limestone, etc.)

- Quarries & Aggregates Production

- Road Construction & Demolition Projects

- Tunneling & Excavation

- Infrastructure Development

✴ Don't let downtime impact profitability. Contact Master Rock Tools today for a quote or to inquire about our extensive inventory of hydraulic rock breaker parts ✴Coal Cutting Picks

Unleash Peak Performance: Premium Coal Cutting Picks for Maximum Extraction

Introduction: Our coal cutting picks are meticulously designed and manufactured to provide exceptional performance and extended durability in demanding underground and opencast coal mining operations. Each pick is constructed from a robust, high-strength steel body, precision-forged for optimal toughness, and features a high-grade tungsten carbide tip. The carbide tips are carefully selected for their hardness and wear resistance, and securely brazed to the steel body, ensuring maximum impact absorption and resistance to abrasion.

The optimized geometry of our picks facilitates efficient penetration into various coal seams, minimizing energy consumption and maximizing cutting speed. This results in higher productivity, reduced wear on your cutting machine, and lower overall operating costs. We offer a comprehensive range of picks tailored for different cutting applications and machine types, including:

-

Radial Picks (Conical Picks): Versatile for continuous miners, longwall shearers, and roadheaders, offering excellent rotation and self-sharpening properties.

-

Tangential Picks: Designed for specific cutting patterns, providing strong impact and effective material removal.

-

Flat Picks: Used for scraping and grading applications.

.

Key Features:

- Tungsten Carbide Tips: For exceptional hardness and wear resistance.

- Optimized Geometry: Designed for efficient material removal and reduced energy consumption.

- Robust Construction: Withstands high impact forces and abrasive materials.

- Versatile Applications: Suitable for road milling machines, pilling rigs, and coal crushers.

Crusher Spare Parts

Optimize Performance & Maximize Uptime: Engineered for Toughness, Unmatched Durability & Performance, Precision Wear Life & High Impact

Introduction: Keep your crushing operation running efficiently and profitably with our extensive range of high-quality stone crusher spare parts. Engineered for maximum durability and optimal performance, our components are manufactured from advanced wear-resistant alloys and subjected to rigorous quality control.

-

Impact Crusher Spares (HSI & VSI): Achieve superior fragmentation and consistent product size with our durable Impact Crusher Spare Parts. Our inventory includes high-chrome Blow Bars and Hammers designed for extreme impact resistance, alongside robust Liner Plates and Rotor components. Extend the service life of your Horizontal (HSI) or Vertical Shaft (VSI) Impact Crusher with parts built for the toughest crushing tasks.

-

Blow Bars / Hammers: High chrome, martensitic steel, or ceramic inserts for maximum impact and abrasion resistance.

-

Impact Plates/Liner Plates: Protect the crusher housing and contribute to the crushing action.

-

Rotors, Anvils, Wear Shoes, Distributor Plates: Key components for material propulsion and crushing in VSI and HSI crushers.

-

High-Performance VSI Rotor Tips: Premium wear parts for VSI crushers. High-chrome alloys for extended life and superior cubical product. Maximizes efficiency and reduces costs.

-

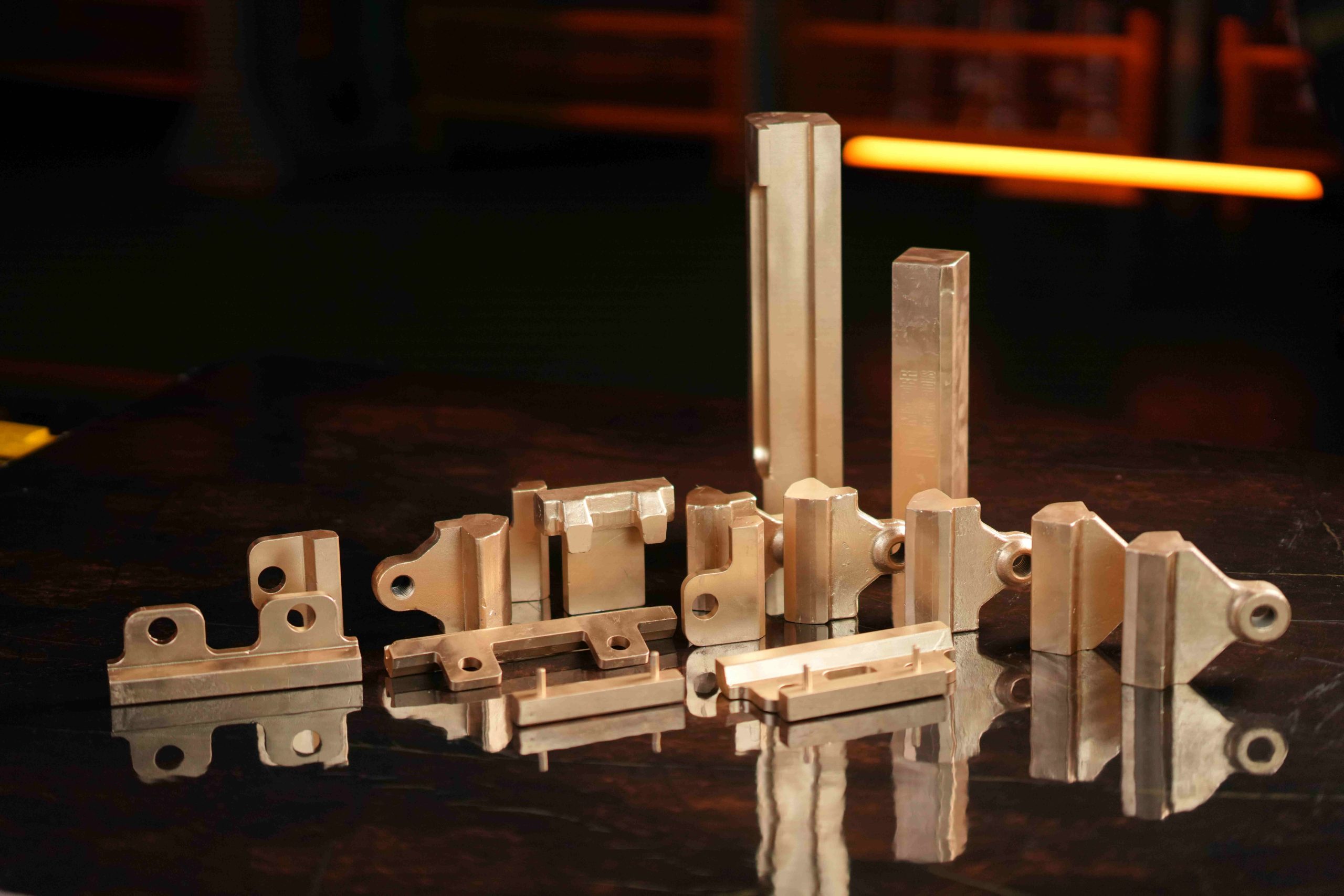

Precision-Engineered Crusher Eccentric Bush: Premium bronze alloy bush for crusher eccentric shafts. Ensures smooth motion, high load capacity, and extended crusher lifespan. Precision engineered.

-

Why Partner with Us for Your Crusher Parts?

-

Superior Material Quality: Utilizing specialized alloys and advanced heat treatments for extended lifespan.

-

Precision Manufacturing: Parts engineered to OEM specifications for seamless fit and optimal machine performance.

-

Exceptional Wear Life: Maximizes operational hours between changes, reducing maintenance frequency.

-

Corrosion Resistance: Bronze composition provides excellent resistance to environmental factors.

-

Precision Fit: Manufactured to exacting tolerances for seamless integration with OEM and aftermarket rotors.

-

Reduced Operating Costs: Less frequent replacements and improved efficiency save you money over time.

-

Broad Compatibility: Spares available for a wide range of crusher brands.

-

Reliable Supply Chain: Minimize downtime with readily available stock and efficient logistics.

-

Expert Support: Our team can help you identify the correct parts for your specific crusher model and application.

Key Features:

- Tungsten Carbide Tips: For exceptional hardness and wear resistance.

- Optimized Geometry: Designed for efficient material removal and reduced energy consumption.

- Robust Construction: Withstands high impact forces and abrasive materials.

- Versatile Applications: Suitable for VSI & HSI Stone Crushers.