Me Forge-Tech (Unit – II)

Forging Services

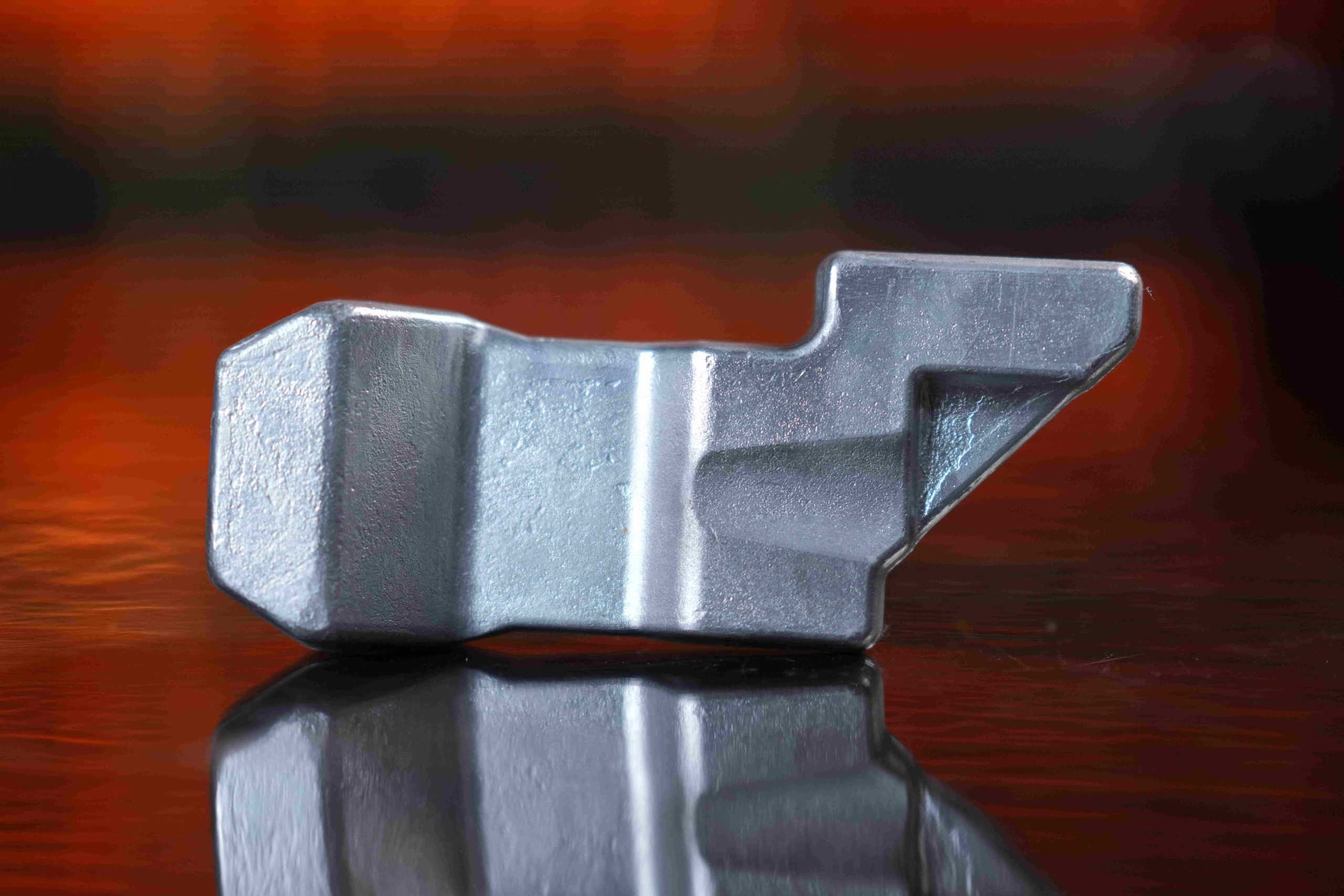

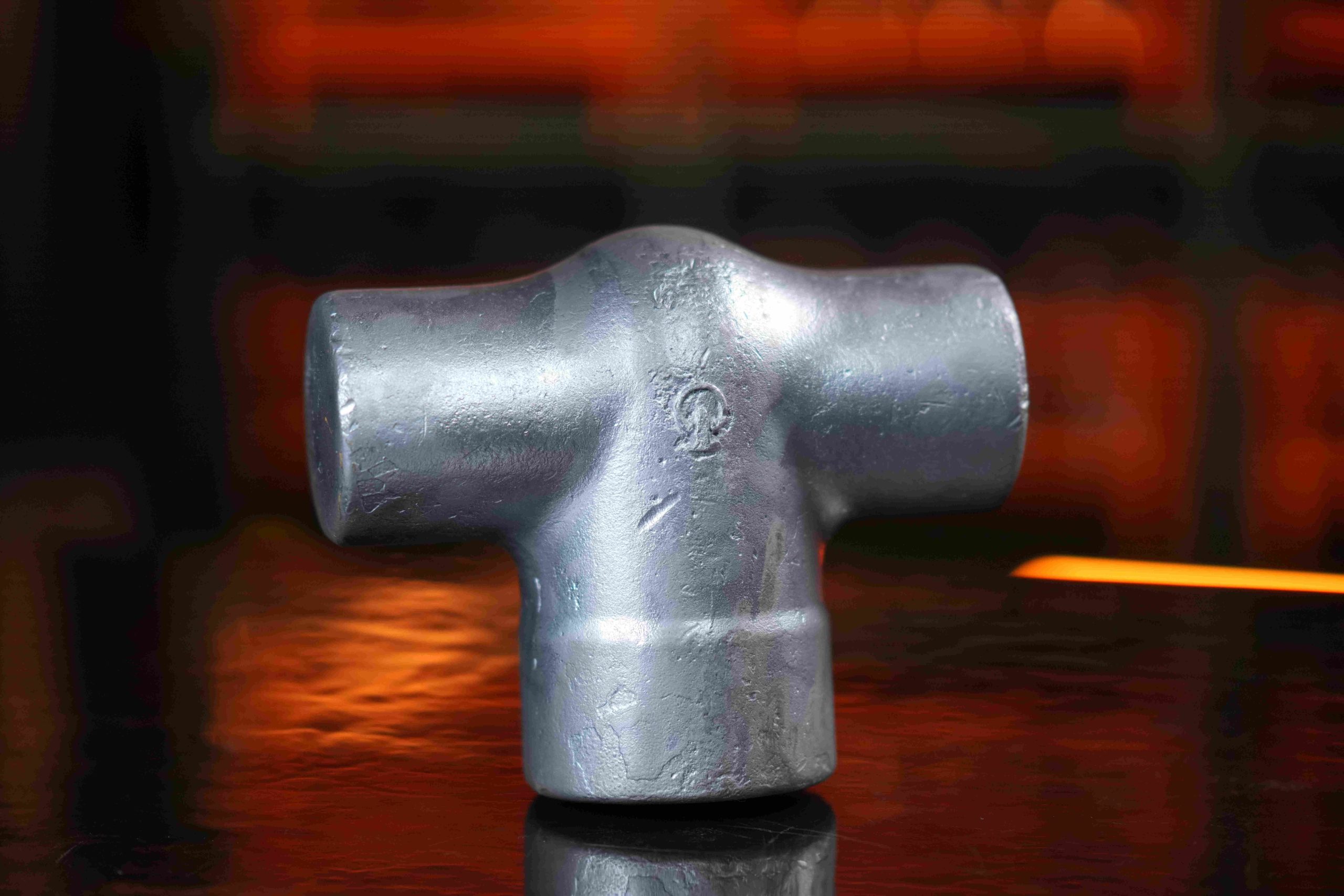

The Advantage of Accuracy: Reliable Die Forgings for Complex Components

At ME Forge (Unit – 2), we specialize in advanced Die Forging (also known as Impression Die Forging or Closed Die Forging) – a highly precise manufacturing process critical for producing components with superior strength, intricate geometries, and exceptional dimensional accuracy. We leverage state-of-the-art technology and deep metallurgical expertise to deliver high-quality, cost-effective forged parts that meet the rigorous demands of India’s leading industries.

Our Die Forging Capabilities & Process:

-

Precision Tooling: Our expertise begins with the design and manufacturing of high-precision dies. The quality of the die directly impacts the final product, and our in-house capabilities ensure optimal die life and consistent part accuracy.

-

Material Versatility: We proficiently work with a wide range of ferrous and non-ferrous metals, including various grades of Carbon Steel, Alloy Steel, Stainless Steel, Aluminum, Copper, and Brass. Our metallurgists assist in selecting the ideal material for your specific application’s strength, wear, and corrosion resistance requirements.

-

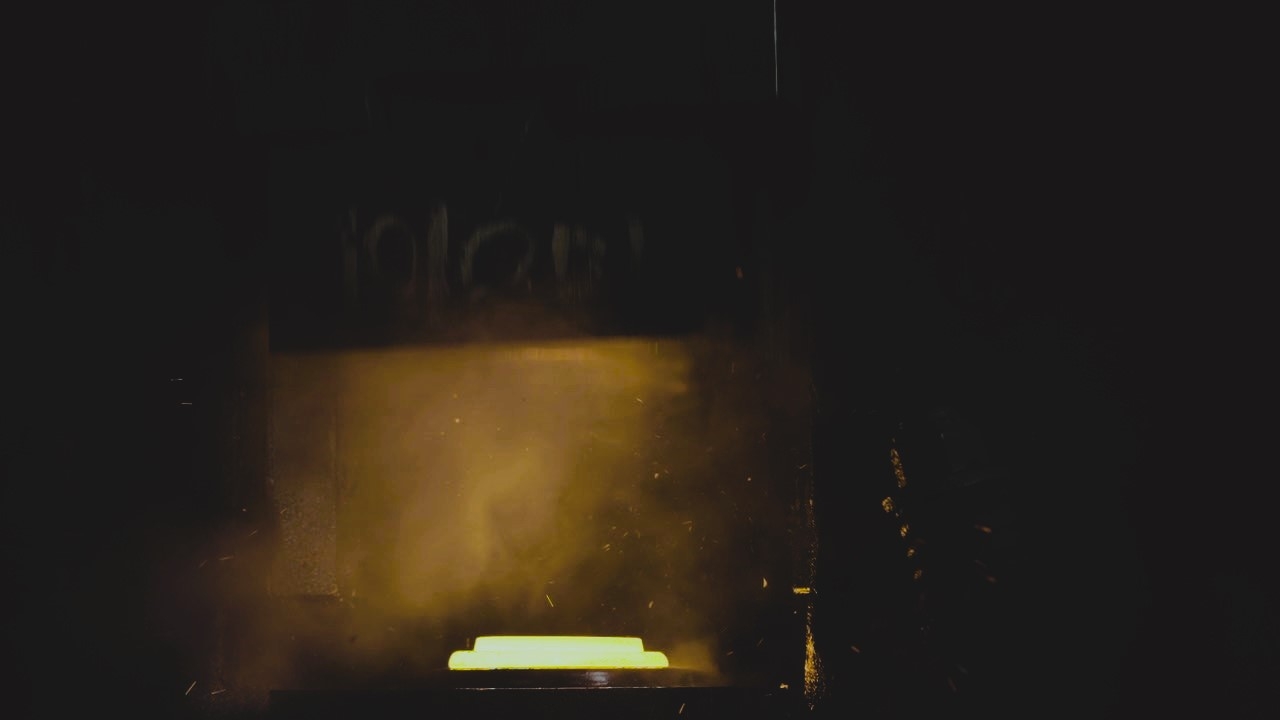

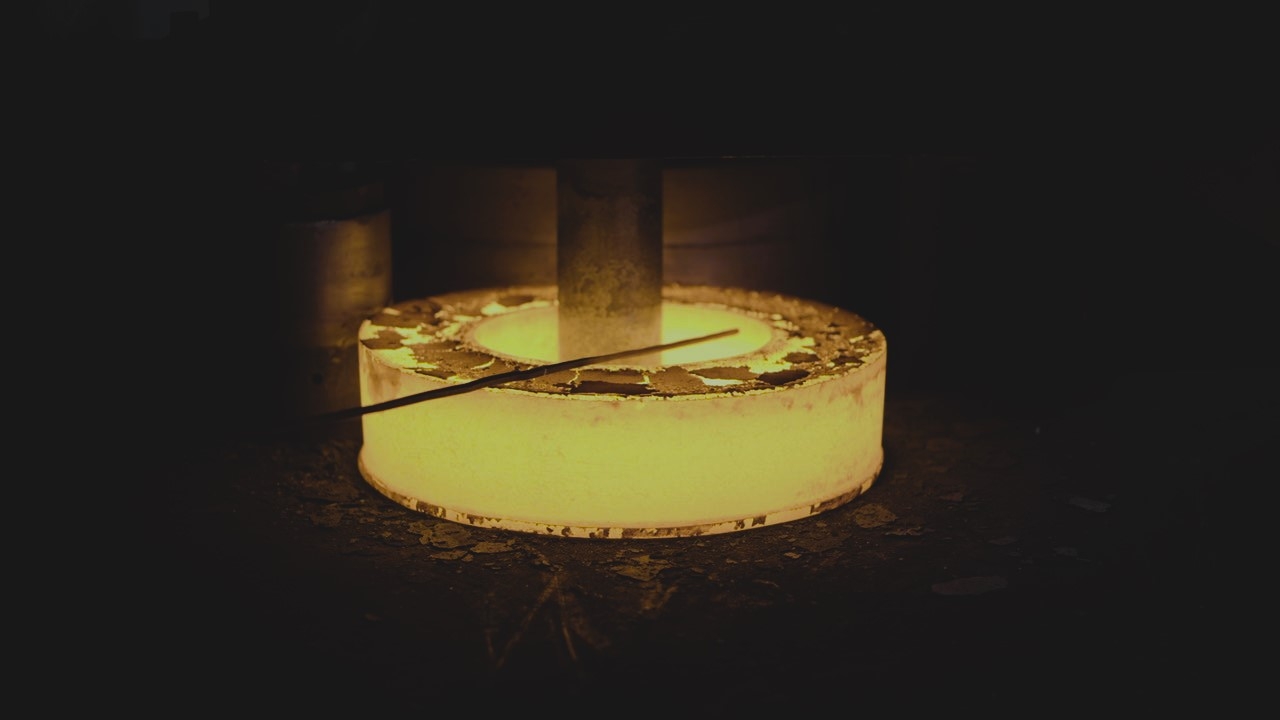

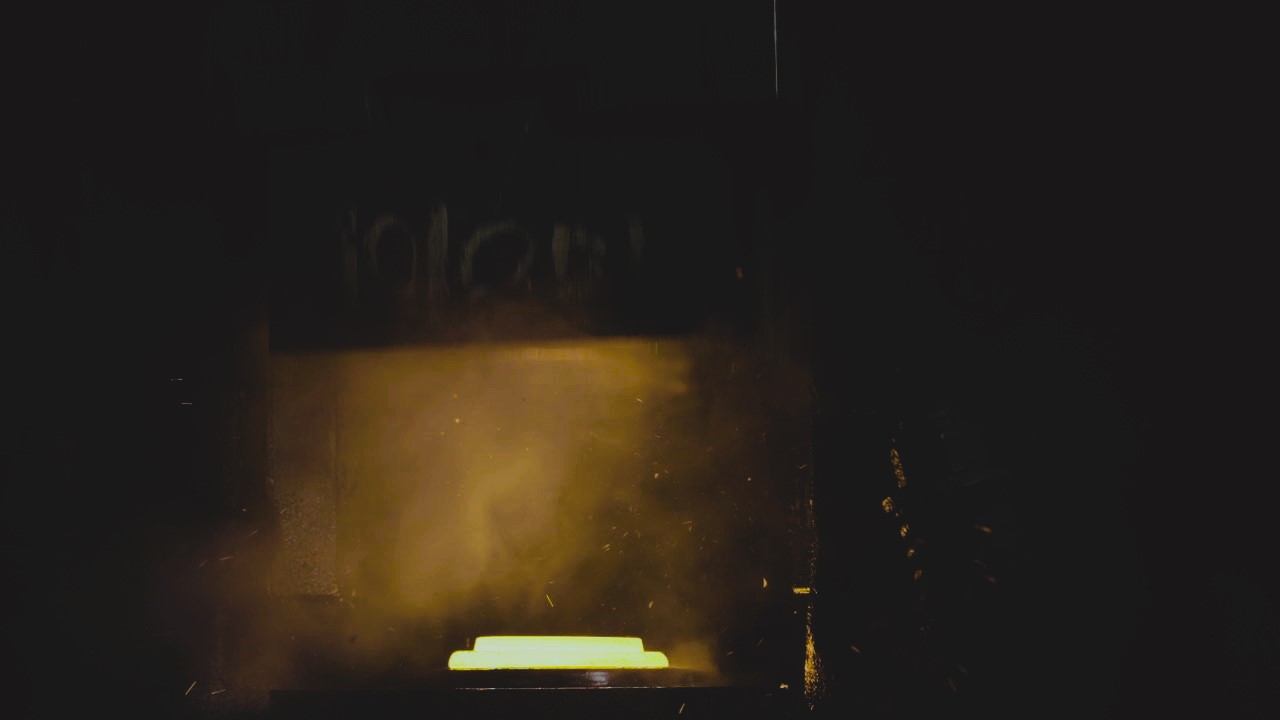

Controlled Heating: Advanced furnaces ensure precise temperature control, preparing the metal to achieve optimal ductility for forging, preventing defects and ensuring uniform material flow.

-

High-Pressure Forging: Utilizing modern forging presses and hammers, we apply immense force to shape the metal, ensuring complete die fill and superior grain refinement.”

-

Post-Forging Processes: “Our capabilities extend beyond forging to include essential secondary operations such as:

-

Trimming: Removing excess flash for a clean, near-net shape.

-

Heat Treatment: Annealing, normalizing, quenching, and tempering to achieve desired mechanical properties (hardness, toughness, ductility).

-

Shot Blasting: For surface finishing and improved fatigue resistance.

-

Machining (Optional): Precision machining to achieve final dimensions and surface finishes as per specifications.

-

Key Advantages of Choosing Our Die Forged Components:

-

Superior Mechanical Properties: Parts exhibit significantly higher tensile strength, yield strength, and fatigue resistance compared to cast or fabricated alternatives, thanks to optimized grain flow and internal integrity.

-

Exceptional Dimensional Accuracy & Consistency: The die cavity ensures repeatable, precise dimensions across large production runs, minimizing variations and reducing the need for extensive post-forging machining.

-

High Production Volumes: Die forging is ideal for cost-effective mass production of identical components, making it perfect for industries requiring high volumes.

-

Reduced Material Waste: The near-net-shape nature of die forging minimizes material loss (flash), leading to greater efficiency and cost savings.

-

Improved Surface Finish: Forged surfaces are typically smoother and free from porosity, enhancing aesthetics and performance.

-

Design Flexibility: Capable of producing complex and intricate shapes with internal cavities and multi-directional grain flow.

Typical Applications & Industries Served (Focus on Indian context):

Our precision die forgings are vital components in industries where reliability and performance are non-negotiable, including:

-

Automotive: Engine components (connecting rods, crankshafts), transmission parts, steering knuckles, suspension arms, gears.

-

Heavy Machinery & Construction: Excavator parts, crane components, agricultural equipment, hydraulic fittings, specialized fasteners.

-

Oil & Gas: Valve bodies, flanges, connectors for high-pressure and high-temperature environments.

-

Railway: Track components, braking system parts.

-

Defence & Aerospace: Critical structural and engine components.

-

Hand Tools: Wrenches, pliers, hammers, and other robust tools.

-

General Engineering: Custom components requiring high strength and fatigue life.

Contact < forge@mastergroup.co.in > in Bengaluru, discuss your specific forging requirements