Master heat treaters pvt ltd

Overview

Master Heat Treaters Pvt. Ltd. has a huge working area with skilled staff and technicians. The company has been serving valuable customers like Ace Designers, BHEL, TVS, and ISRO.

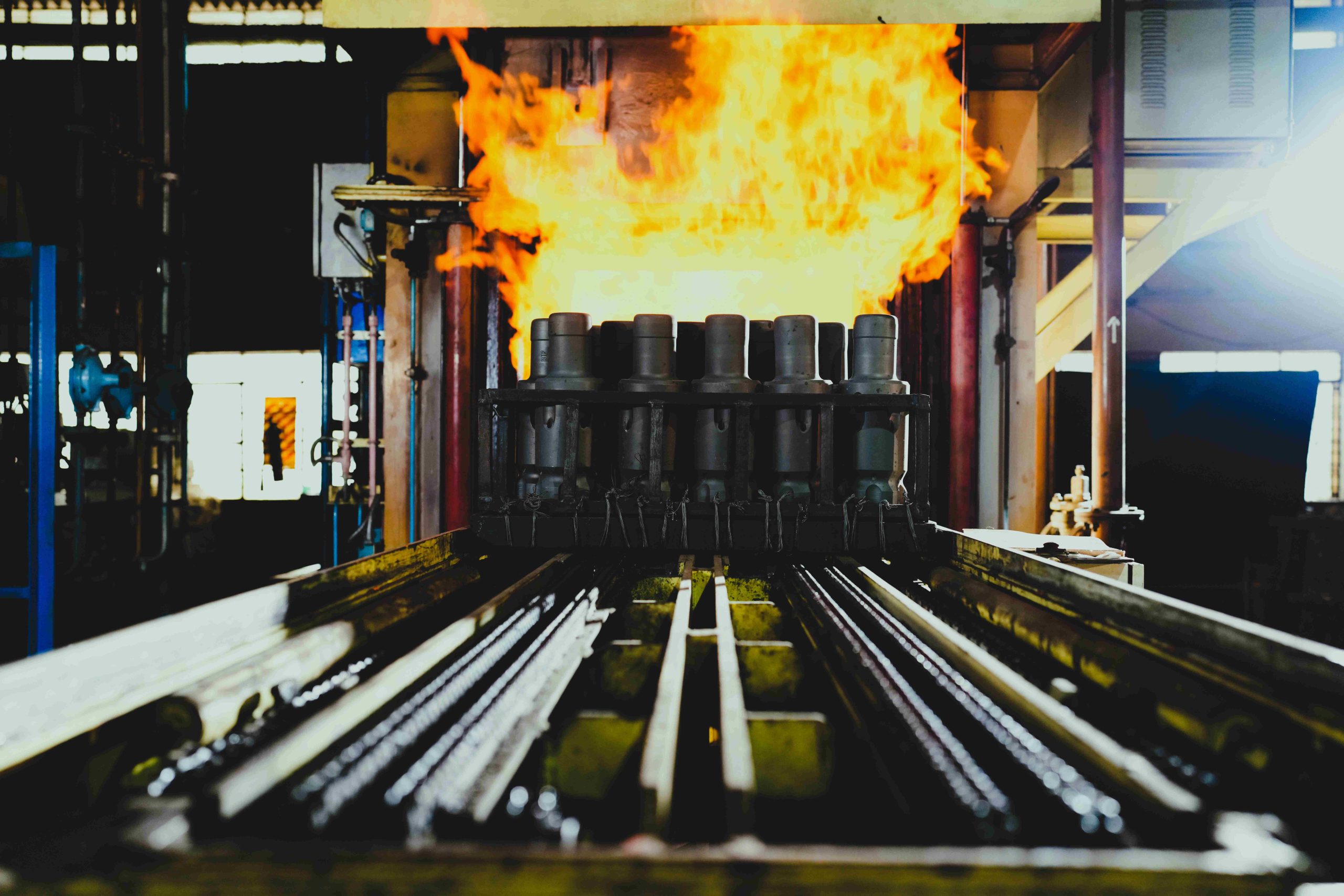

Heat Treatment Services

At Master Heat Treatment, located in the industrial heart of Bengaluru, Karnataka, we specialize in providing advanced metal heat treatment services that transform the inherent properties of metals. Through carefully controlled heating and cooling processes, we enhance the strength, hardness, ductility, toughness, and machinability of various metal components. Our expertise ensures that your materials meet the most stringent performance requirements for critical applications across diverse industries.

Understanding Metal Heat Treatment

Heat treatment is a fundamental metallurgical process that involves altering the physical and sometimes chemical properties of a material. By precisely controlling temperature cycles and atmospheric conditions, we can modify the microstructure of metals and alloys, tailoring them to exhibit specific desired characteristics for their intended use. This crucial step is vital for improving component longevity, reliability, and overall performance.

Our Comprehensive Heat Treatment Capabilities

We offer a wide range of heat treatment processes, meticulously executed by our experienced metallurgists and technicians, utilizing state-of-the-art equipment:

- Hardening: Heating steel to a specific temperature and rapidly cooling it (quenching) to achieve maximum hardness and strength.

- Tempering: Reheating hardened steel to a lower temperature to reduce brittleness and improve toughness and ductility, while retaining sufficient hardness.

✵ Ideal For: Gears, shafts, cutting tools, springs, and high-stress components.

- Annealing: Heating metal to a specific temperature and slowly cooling it to relieve internal stresses, improve ductility, refine grain structure, and enhance machinability.

✵ Ideal For: Making metals softer for further processing (forming, machining) or reducing brittleness after cold working.

- Normalizing: Heating steel above its critical temperature and then air-cooling it to refine the grain structure, improve strength and toughness, and achieve a more uniform microstructure.

✵ Ideal For: Components that require improved strength without significant hardness increase, or for preparing steel for further heat treatment.

- Case Hardening (Carburizing/Nitriding): Processes that introduce carbon (carburizing) or nitrogen (nitriding) into the surface of a component to create a hard, wear-resistant outer layer while maintaining a tough, ductile core.

✵ Ideal For: Components requiring high surface hardness for wear resistance, such as gears, cams, and pins.

- Stress Relieving: Heating a component to a sub-critical temperature followed by slow cooling to reduce residual stresses introduced during manufacturing processes like welding, machining, or cold forming, preventing distortion and cracking.

✵ Ideal For: Welded structures, precision machined parts, and large castings/forgings.

- Solution Annealing & Age Hardening (for Non-Ferrous Alloys): Specific processes for alloys like aluminum and some stainless steels, involving heating to dissolve alloying elements, followed by quenching and controlled aging to achieve optimal strength.

✵ Ideal For: Aerospace components, automotive parts, and high-strength aluminum alloys.

Why Choose Master Heat Treaters?

- Metallurgical Expertise: Our team of qualified metallurgists possesses in-depth knowledge of material science, ensuring optimal heat treatment recipes for your specific alloys and applications.

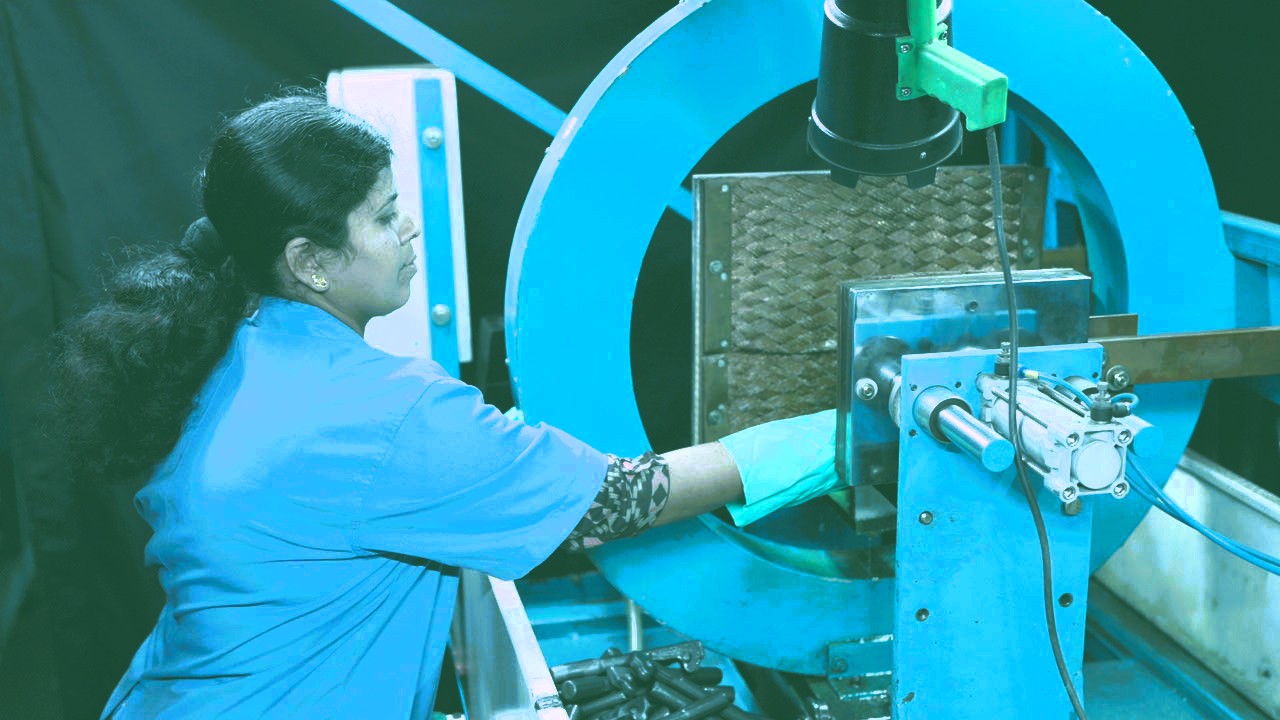

- State-of-the-Art Facilities: Equipped with advanced furnaces, precise temperature control systems, and robust quenching capabilities, ensuring consistent quality and repeatability.

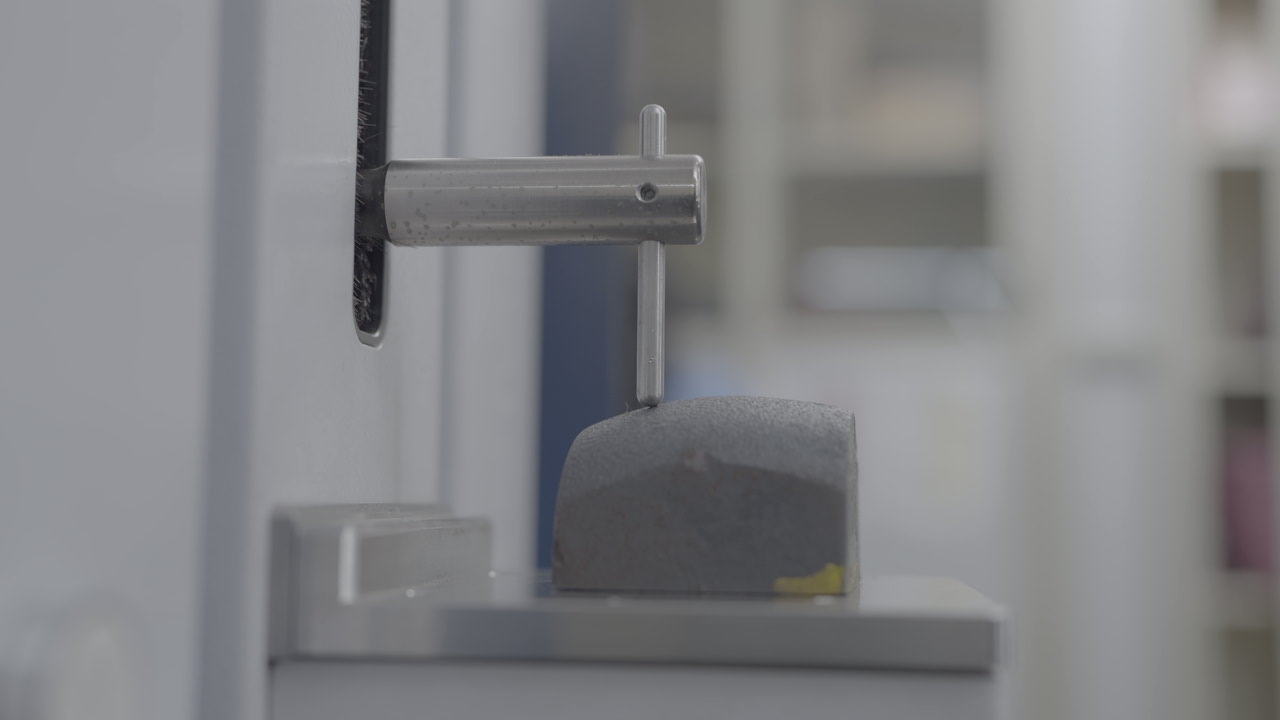

- Quality Assurance: We adhere to stringent quality control protocols, including hardness testing, microstructure analysis, and [mention any relevant certifications, e.g., ISO 9001:2015] to guarantee adherence to specifications.

- Customized Solutions: We work closely with clients to understand their unique requirements, offering tailored heat treatment solutions for individual components or large batches.

- Located in Peenya, Bengaluru: Our strategic location ensures efficient logistics, quick turnaround times, and reliable service for businesses across the region and beyond.

- Diverse Material Handling: Expertise in treating a wide range of materials including various grades of Carbon Steels, Alloy Steels, Stainless Steels, Tool Steels, Cast Irons, Aluminum Alloys, Copper Alloys, and more.

Applications Across Industries

Our heat-treated components are vital in:

Automotive & Auto Ancillary: Gears, crankshafts, shafts, engine components.

Aerospace & Defense: Structural components, precision parts.

Heavy Machinery & Construction: Pins, bushings, linkages, wear parts.

Tool & Die: Molds, dies, cutting tools.

Oil & Gas: Valve components, pump parts.

General Engineering: Fasteners, custom machinery parts.

Beyond Raw Strength, Precision Heat Treatment for Superior Metal Properties

Write your enquiry to heattreat@mastergroup.co.in to discuss your specific requirements