Master Mining Equipments

Overview

” Master Mining Equipments the primary and initiative company of Master Group was formed in the year 2000. Pioneer manufacturer of DTH Borewell Bits.

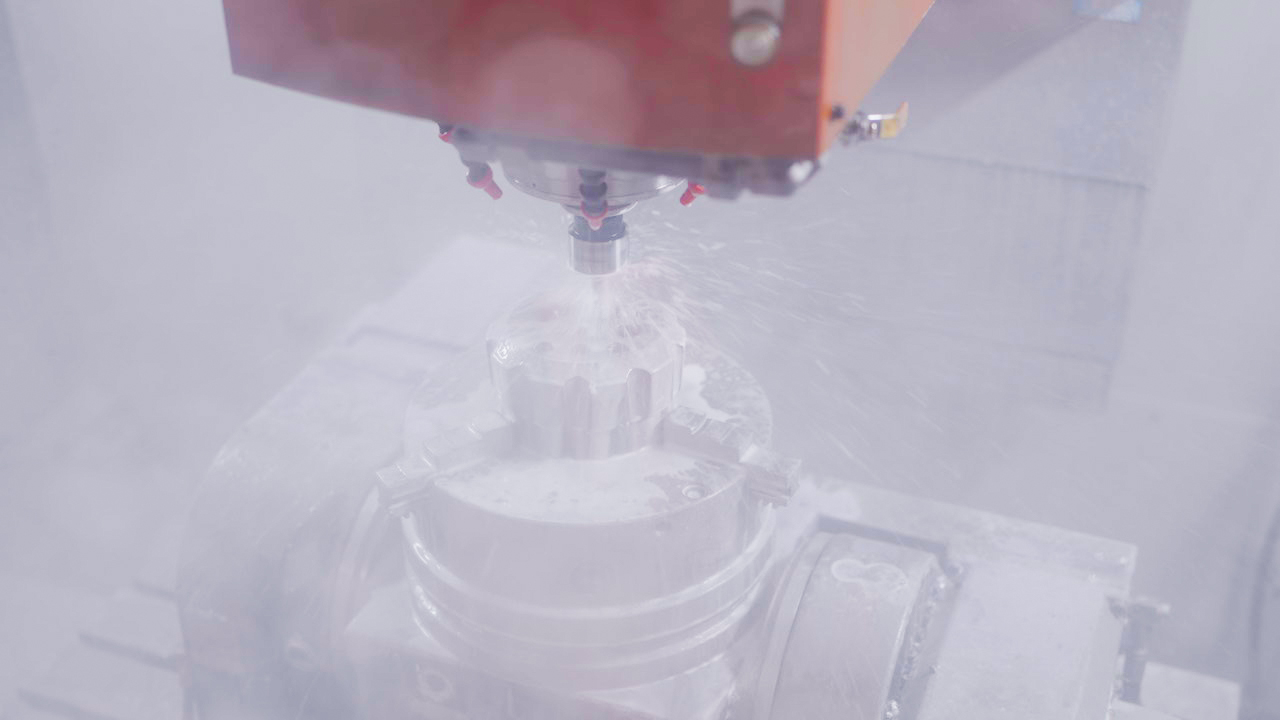

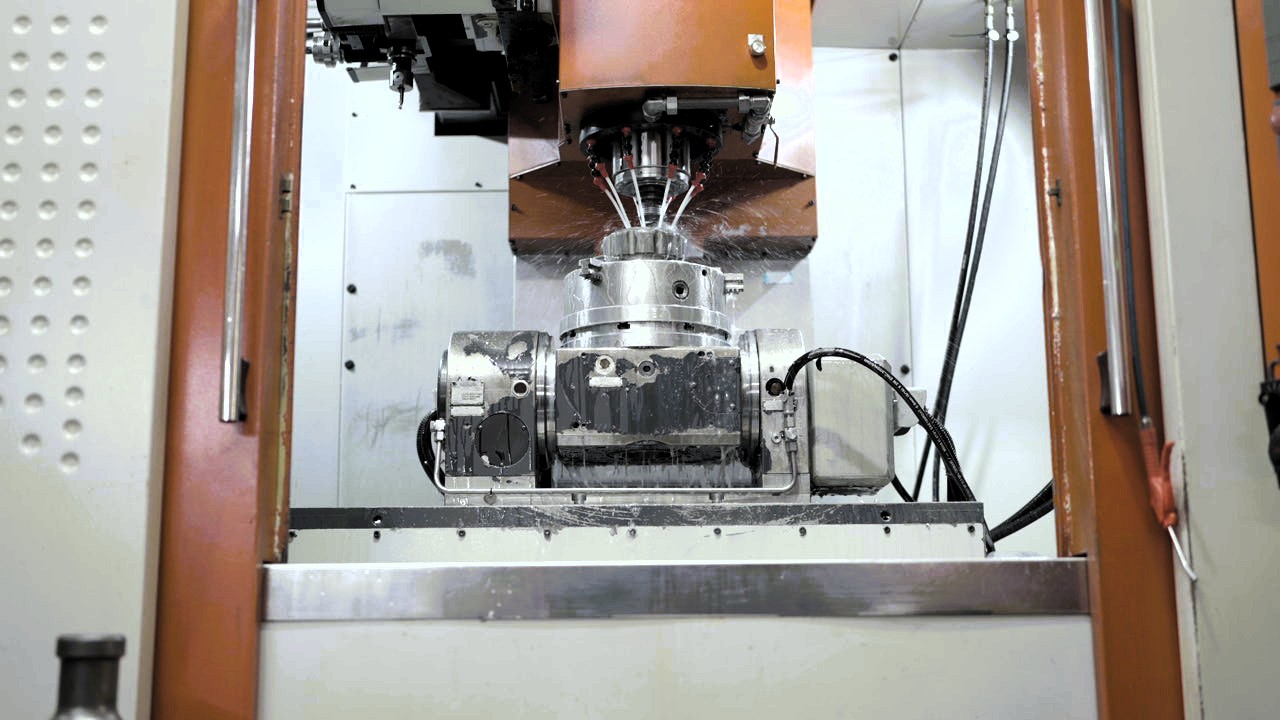

MME has a huge manufacturing premises with well trained staff and technicians. It also has high performance CNC, Milling, Drilling, Turning and Grinding machines and quality systems that manufacture high efficiency bits. “

Down The Hole (DTH) Button Bits

Unleash Unrivaled Performance: Advanced Down The Hole (DTH) Drilling Systems

Engineered for the most demanding rock drilling applications, our comprehensive range of Down The Hole (DTH) Hammers and meticulously matched Drill Bits represents the pinnacle of drilling technology. Designed for industries ranging from large-scale mining and quarrying to intricate civil engineering and water well development, our DTH systems are meticulously crafted to deliver unparalleled penetration rates, exceptional hole accuracy, and extended operational lifespans.

Our DTH Hammers: Precision-Engineered for Maximum Impact Energy

At the core of our DTH system lies our advanced hammer design. Each hammer is precision-machined from high-grade alloy steels, undergoing rigorous heat treatment processes to ensure superior wear resistance and fatigue strength in extreme conditions.

Optimized Air Cycle: Featuring an innovative internal air distribution system that maximizes energy transfer to the piston, resulting in higher impact frequency and a more powerful blow. This optimized air cycle translates directly into faster drilling and reduced air consumption per meter drilled, improving overall fuel efficiency.

Robust Piston Design: Our pistons are designed for maximum kinetic energy transfer, ensuring efficient rock breaking even in the hardest formations. Close tolerances and superior surface finishes minimize internal wear and maintain peak performance over extended periods.

Simplified Maintenance: Designed with fewer internal components and robust construction, our hammers facilitate quicker disassembly and assembly, significantly reducing downtime for servicing and part replacement.

Versatile Shank Options: Available with industry-standard shanks (e.g., DHD, SD, QL, COP, Mission) to ensure seamless compatibility with a wide array of existing drill rigs and drilling patterns.

Our DTH Drill Bits: Cutting-Edge Designs for Optimal Rock Disintegration

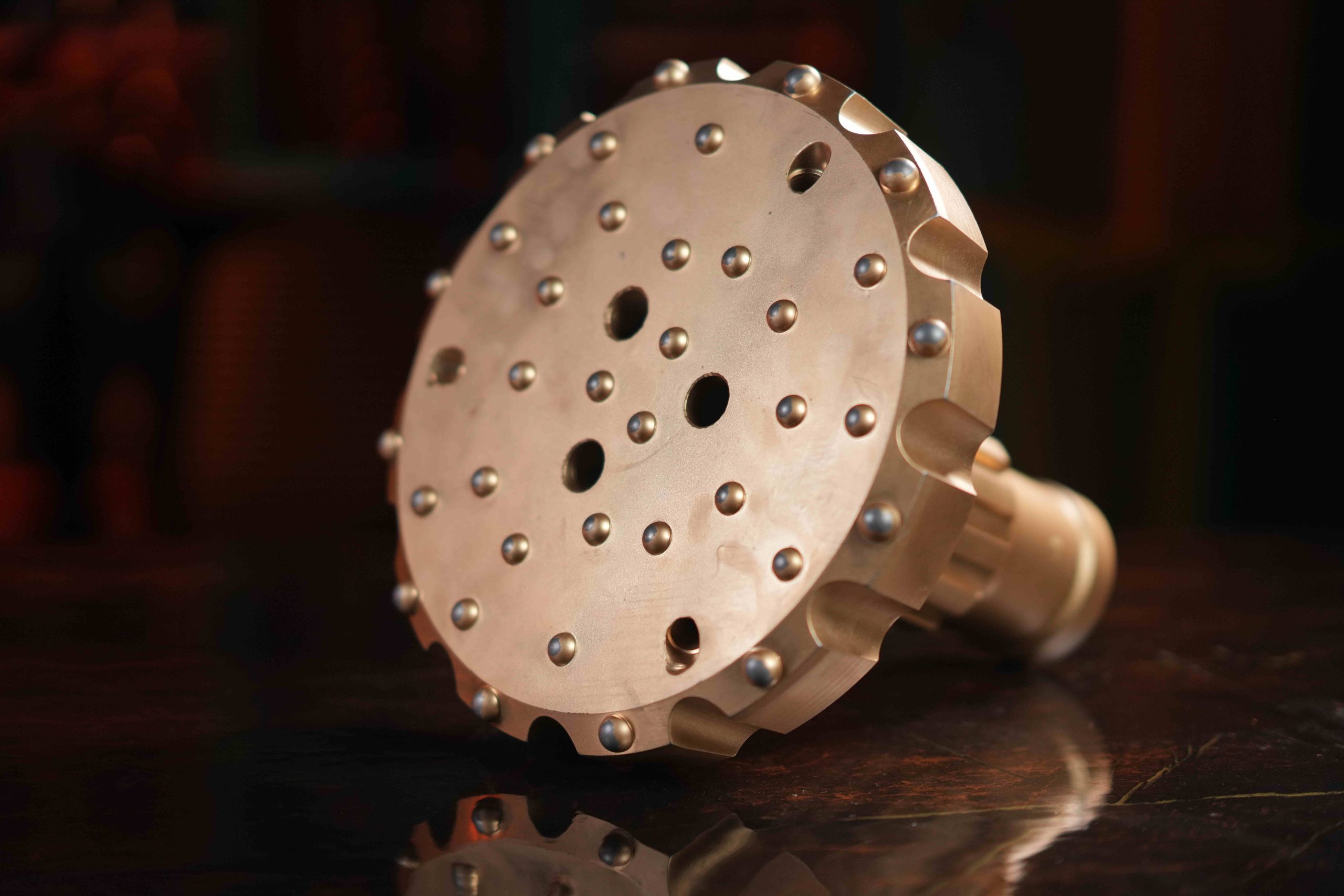

Complementing our powerful hammers, our DTH drill bits are the embodiment of cutting-edge metallurgical science and geotechnical design. Each bit is tailored for specific rock conditions, ensuring maximum efficiency and longevity.

Premium Tungsten Carbide Inserts: Utilizing only the highest quality, application-specific tungsten carbide inserts (buttons), strategically placed for optimal rock fracturing. Available in various button shapes (domed, ballistic, parabolic) to suit abrasive, fractured, or competent rock types, maximizing penetration and wear life.

Advanced Face Designs: Choose from a range of bit face profiles – including Flat Face for straight-hole drilling in hard, abrasive rock; Convex Face for maximum penetration in medium-hard formations; and Concave Face for superior hole deviation control in softer, fractured rock.

Optimized Flushing Holes: Precisely positioned and sized flushing holes ensure efficient evacuation of cuttings, preventing regrinding and maintaining a clean borehole, which further contributes to higher penetration rates and extended bit life.

Heat-Treated Alloy Steel Body: The bit body is forged from premium alloy steel and undergoes advanced heat treatment to resist wear, impact, and fatigue, providing a robust platform for the carbide inserts.

Key Technical & Operational Advantages:

Superior ROP (Rate of Penetration): Achieve industry-leading drilling speeds, directly translating to reduced project timelines and increased profitability.

Enhanced Hole Quality: Consistent and precise boreholes, minimizing deviation and ensuring optimal conditions for subsequent operations (e.g., blasting, casing installation).

Reduced Cost Per Meter: The combination of high penetration rates, extended tool life, and optimized energy consumption significantly lowers your overall drilling expenditure.

Durability in Harsh Environments: Engineered and tested to withstand extreme temperatures, abrasive conditions, and high-pressure demands, ensuring reliable performance in the toughest geological settings.

Comprehensive Size & Type Range: A vast inventory of hammers and bits in various diameters and configurations to meet virtually any drilling challenge.

Expert Technical Support: Our team of drilling specialists is available to provide application-specific recommendations and troubleshooting, ensuring you select the optimal DTH system for your unique project requirements.

✴ Invest in our Down The Hole drilling solutions and experience a tangible increase in your operational efficiency, productivity, and profitability ✴