Services

Forging

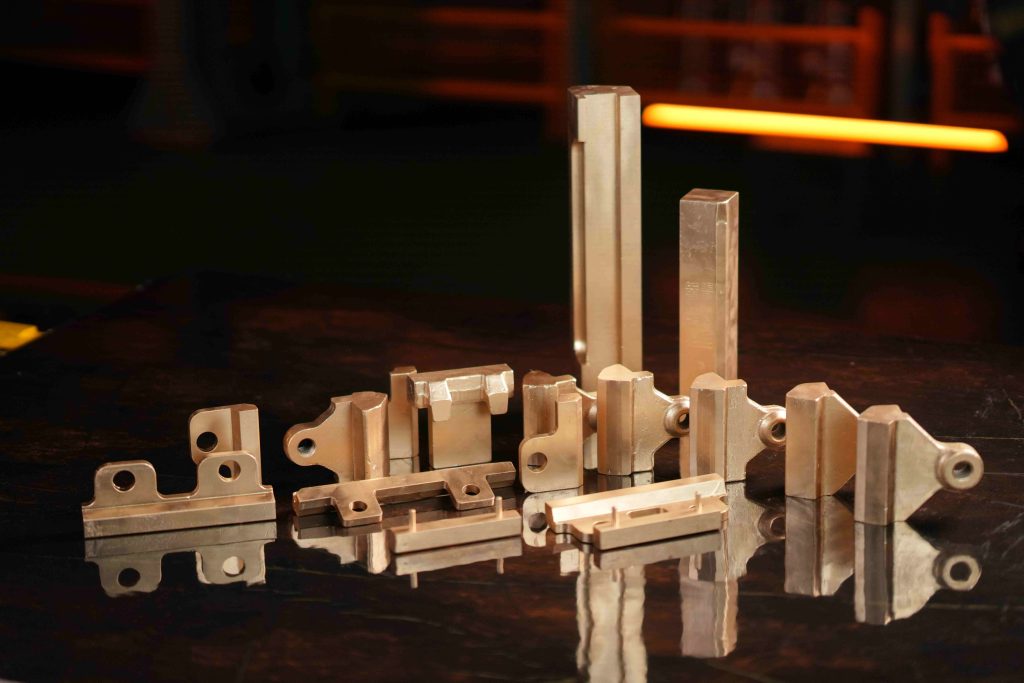

Open, Closed & Ring Forgings in All Metals

Established in 2007, M/s ME Forge Tech emerged as a trusted name in the forging industry, inspired by the success of its sister concerns. Located within its own expansive industrial premises, the company specializes in Open, Closed, and Ring Forgings using both ferrous and non-ferrous metals.

We manufacture a wide range of high-quality forged components, including:

- Gear Blanks, Flats, Wheels and Couplings

- Rings, Rings Gears, Seat Rings, Thrust Rings, Guard Rings, Hubs and Spacers

- Cylinders, Square Solids, Guide ways, Pistons, Swivel Shagts, Pulley Forgings

- Head Cylinders, Drum Forgings, Bush Forgings

- Shaft Centers, Flange Forgings, Step Shafts, Connecting Rods, Plain Shafts and Solid Blocks

- Shafts, Pinion Shafts, Yoke Shafts and Crank Shafts

- Spindles and Step Forgings

- Bonnets and Lock Open Caps

- Head Pistons , Slab Gates and Valves

Our Forging Units

ME Forge Tech (Unit - I)

ME Forge Tech (Unit – II)

ME Forge Tech is equipped with 5 high-capacity hammers and advanced forging machinery, ensuring high-quality output and efficient production timelines. Our commitment to excellence has earned us the trust of leading industry players such as Ace Designers, BHEL, BEML, and various other reputed public sector units.

Heat Treatment

Advanced Heat Treatment & Metallurgical Solutions

Master Heat Treaters Pvt. Ltd., a sister concern of M/s ME Forge Tech, Bangalore, was established with a mission to lead in the field of Heat Treatment and Allied Metallurgical Services. Backed by technical expertise and modern infrastructure, we provide reliable and precise heat treatment solutions tailored to industry needs.

We also operate a fully-equipped Metallurgical Laboratory featuring

- MicroVickers Hardness Tester

- Metallurgical Microscope

- Spectroscope

- Sealed Quenching

- Pit Furnaces

- Gas Carburising

- Gas Nitrating

- Tempering

- Hardening

Our Heat Treatment Units

Master heat treaters pvt ltd

SS heat treaters

Precision Engineering Works

High-Precision Machining and Reliable Results.

The Master Group, established in 2000, has grown steadily through its commitment to engineering excellence. Over the years, the group has expanded into specialized verticals of machining and component manufacturing, catering to industries like automobile, earthmoving, aerospace, mining, and construction.

We cater to global clients, including John Crane and Enerpac, producing high-precision components like:

- Jaw Plates

- Cone Mantles

- VSI Tips & Wear Plates

- Cone Crusher Bushes

- Thrust Bearings, Plates, and more – all in LTB5 material grade.

Precision Services for Demanding Industries

Customized Engineering Products

We specialize in the design and manufacturing of Customized Engineering Products to meet the specific needs of various industries including automobile, aerospace, mining, construction, and earthmoving.

Mining Equipments

Efficiency Meets Durability

At Master Group, we specialize in manufacturing durable, high-performance mining equipment designed to meet the toughest industry standards. Our product range is engineered for efficiency, reliability, and long service life—making them ideal for use in drilling, crushing, excavation, and material handling.

Comprehensive Solutions for Drilling & Crushing Needs

Mining Equipment

Founded as the flagship company, Master Mining Equipments manufactures high-efficiency borewell bits using 15 high-performance CNC, milling, drilling, turning, and grinding machines. With a strong foundation of quality and technical expertise, the company continues to serve clients across various sectors.

DTH Hammer & Bits

we specialize in manufacturing high-performance DTH hammers, bits, and spares that meet the demanding requirements of the drilling and mining industries. Our DTH products are engineered for deep hole drilling, offering maximum penetration rates, low air consumption, and longer service life even in the toughest rock formations.

Rock Breaker Spares

Master Group offers a comprehensive range of Rock Breaker Spares designed to ensure smooth operation, reduced downtime, and extended equipment life. Our spares are manufactured using premium-grade materials and precision machining, making them compatible with leading rock breaker brands in the market.

Crusher Spare Parts

Master Group manufactures and supplies high-quality Crusher Spare Parts to support various types of crushers used in mining, quarrying, construction, and recycling industries. Designed for durability, strength, and exact fitment, our parts ensure consistent performance and reduced downtime in heavy-duty applications.